WPC refers to a kind of wood plastic composites (WPC) floor.

WPC uses polyethylene, polypropylene and polyvinyl chloride instead of common resin adhesives, and mixes with more than 50% of wood powder, rice husk, straw and other waste plant fibers to form new wood materials, and then produces plates or profiles through extrusion, molding, injection molding and other plastic processing processes. Mainly used in building materials, furniture, logistics packaging and other industries.

WPC floor features:

1. Good machinability.

Wood plastic composites contain plastics and fibers. Therefore, they have similar processing properties to wood. They can be sawed, nailed and planed. It can be completed with woodworking tools, and the nailing force is obviously better than that of other synthetic materials. The mechanical properties are better than wood. The nailing force is generally three times that of wood and five times that of particleboard.

2. Good strength performance.

Wood plastic composites contain plastics, so they have better elastic modulus. In addition, due to the inclusion of fiber and the full mixing with plastic, it has the same physical and mechanical properties as hardwood, such as compression and bending resistance, and its durability is obviously better than that of ordinary wood. The surface hardness is high, usually 2 to 5 times that of wood.

3. It has the characteristics of water resistance, corrosion resistance and long service life.

Compared with wood, wood plastic materials and products are resistant to acid and alkali, water, corrosion, bacteria, insects and fungi. Long service life, up to 50 years.

| Specification | |

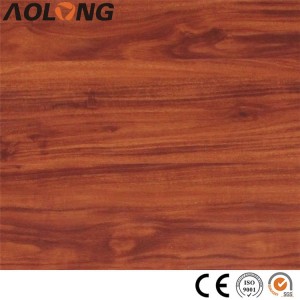

| Surface Texture | Wood Texture |

| Overall Thickness | 10.5mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1200 * 178 * 10.5mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |