SPC floor has the characteristics of green, environment-friendly and very elastic, easy to clean and use, and long service life. It uses natural marble powder to form a solid base with high density and high fiber network structure, which is processed through thousands of processes.

How to maintain SPC floor?

In recent years, SPC floor has been favored by the market. The main reason is that it has good performance. It uses SPC base material for extrusion, and then uses PVC wear-resistant layer, PVC color film and SPC base material for one-time heating, laminating and embossing. It is a product without glue.

But many users don't pay attention to the maintenance of SPC floor after they buy it home, which greatly reduces the life of the floor. This is not worth the loss. Here is a brief introduction of several maintenance knowledge of SPC floor.

1 Clean the floor regularly to keep it dry and beautiful

2 Do not use corrosive cleaning products left on the floor surface

3 When stepping on the floor, place a non rubber doormat outside the door to absorb the dirt on the sole of the foot

4 Do not use sharp products to scratch the floor, which may damage the paint surface of the floor

We always adhere to the business policy of "regarding customers as life, taking quality as foundation, and seeking development through innovation"; we believe in the business moral basis of "honesty based"; we persist in the belief of "pursuing perfection and customer supremacy". We pay close attention to enterprise management and lay a solid foundation for development; we constantly study, research and absorb new technologies to strive for a higher level of products; we always keep awake and never ignore any link in the quality chain.

| Specification | |

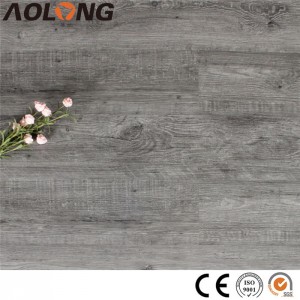

| Surface Texture | Wood Texture |

| Overall Thickness | 6mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1210 * 183 * 6mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |