SPC latch floor

SPC lock lock floor is composed of thickened wear-resistant layer, UV layer, color film texture layer and substrate layer. European and American countries call this kind of floor RVP (rigid vinyl plank), rigid plastic floor. Its base material is a composite board made of stone powder and thermoplastic polymer material after being evenly stirred and then extruded at high temperature. At the same time, it has the properties and characteristics of wood and plastic to ensure the strength and toughness of the floor.

Floor structure

Wear resistant layer: PVC transparent wear-resistant layer, about 0.3mm thick, transparent texture, strong adhesion, wear resistance, scratch resistance, wear resistance coefficient up to 6000-8000 rpm.

UV layer: UV oil is cured by curing agent to form a coating, which can prevent the volatilization of chemical substances in the board by UV.

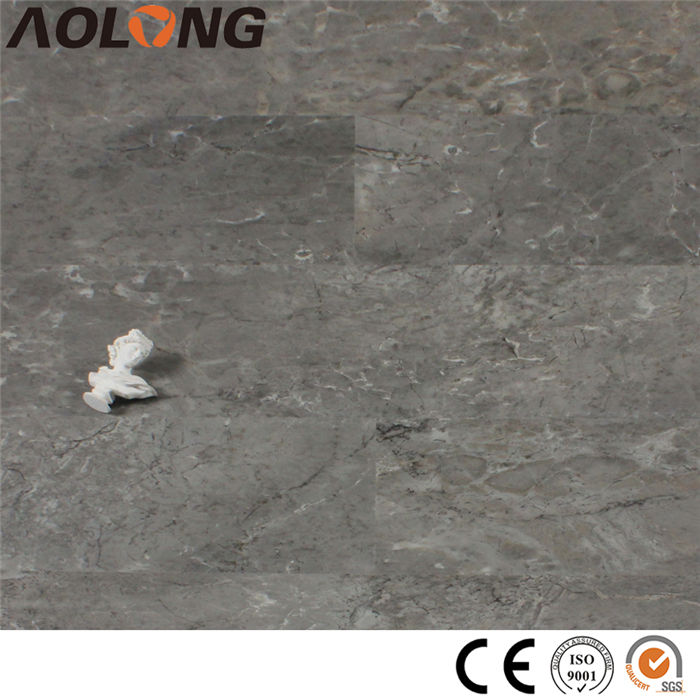

Color film layer: various decorative layers of wood grain, stone grain and carpet grain, which can meet the different needs of different occasions and tastes.

Polymer base material layer: the composite board made of stone powder and thermoplastic polymer material by high temperature extrusion after mixing evenly. It has the properties and characteristics of wood and plastic at the same time, so this kind of floor has good strength and toughness.

| Specification | |

| Surface Texture | Stone Texture |

| Overall Thickness | 3.7mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 935 * 183 * 3.7mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |