For SPC plastic floor, I believe we all want to know the benefits of using SPC plastic floor? Isn't plastic easy to pollute the environment? Listen to Lanfei Xiaobian tell you! Recognize the benefits of products, reasonable use, can better enrich our life, let us live not monotonous!

SPC plastic floor is composed of thickened wear-resistant layer, UV layer, color film texture layer and substrate layer. European and American countries call this kind of floor RVP (rigid vinyl plank), rigid plastic floor. Its base material is a composite board made of stone powder and thermoplastic polymer material after being evenly stirred and then extruded at high temperature. At the same time, it has the properties and characteristics of wood and plastic to ensure the strength and toughness of the floor.

(1) Ecological environmental protection (2) fire protection, fire grade B1, next to stone (3) surface treatment (concave convex, hand scratch, pattern, mirror pattern) (4) wear resistance, wear resistance Grade T (5) moisture-proof, no deformation in water, can be used in the kitchen, toilet, basement, etc. (6) beautiful and diverse colors, seamless splicing construction, convenient and fast installation (7) anti-skid, astringent in water, not easy to fall (8) silencing Walking feet feel comfortable and elastic, and it is not easy to fall down. (9) daily maintenance does not need waxing, and can be wiped with towel or wet mop

| Specification | |

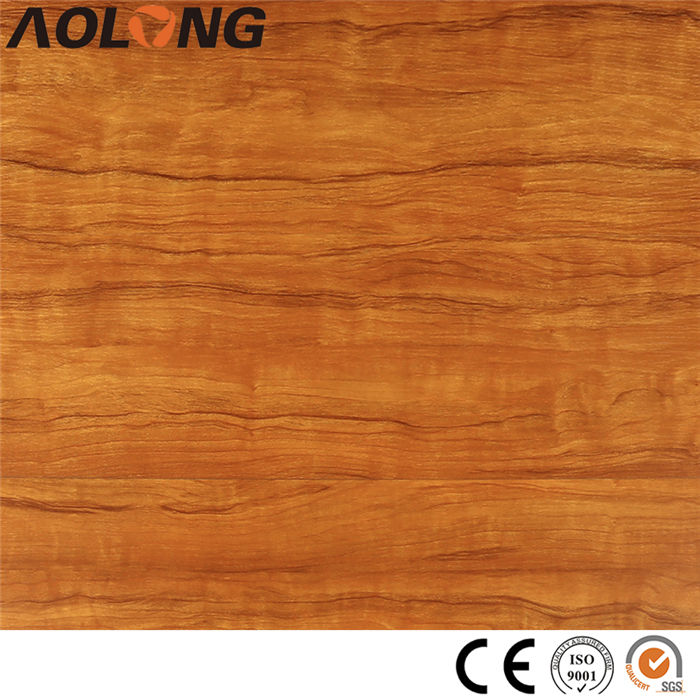

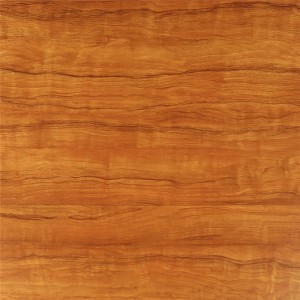

| Surface Texture | Wood Texture |

| Overall Thickness | 6mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1210 * 183 * 6mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |