Renewable Design for Rigid Core Vinyl Flooring - WPC Floor 1055 – Aolong Detail:

With the gradual lack of resources, environmental protection problems are becoming increasingly acute, and countries all over the world are looking for renewable and environmentally friendly new materials. In the United States, most of the states have clearly stipulated that laminate flooring is not allowed to be sold and used, and WPC replaces it. We encourage the development and production of new sustainable materials. At the same time, the Forestry Association and other relevant departments have issued WPC flooring industry standards one after another. Since then, the performance indicators of the product have been clearly defined, which has laid a good foundation for the development of the industry.

WPC floor structure and production technology:

The product as a whole can be divided into two parts, the surface LVT layer itself is a kind of ground environmental protection material (abroad to France Jiefu, Armstrong, the United States). Because it is too thin, and the pavement needs to use glue, it is greatly reduced in environmental protection. And the pavement has higher requirements on the ground, so it needs self leveling, so the cost is greatly increased. On this basis, adding environment-friendly foam substrate can solve various problems of LVT, increase the thickness without self leveling, increase the thickness can be slotted without using glue.

The foaming base material is made up of polymer resin, rock powder and wood fiber powder (both solid) through high-temperature physical friction. The polymer resin reaches the hot melt state (semi fluid) to wrap rock powder and wood powder, and is extruded by machine.

| Specification | |

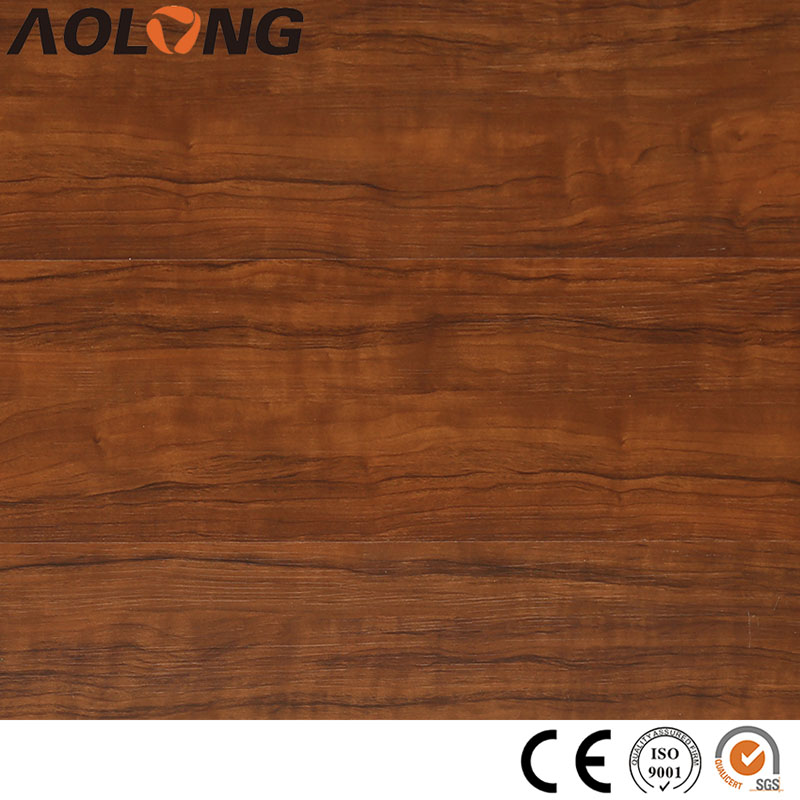

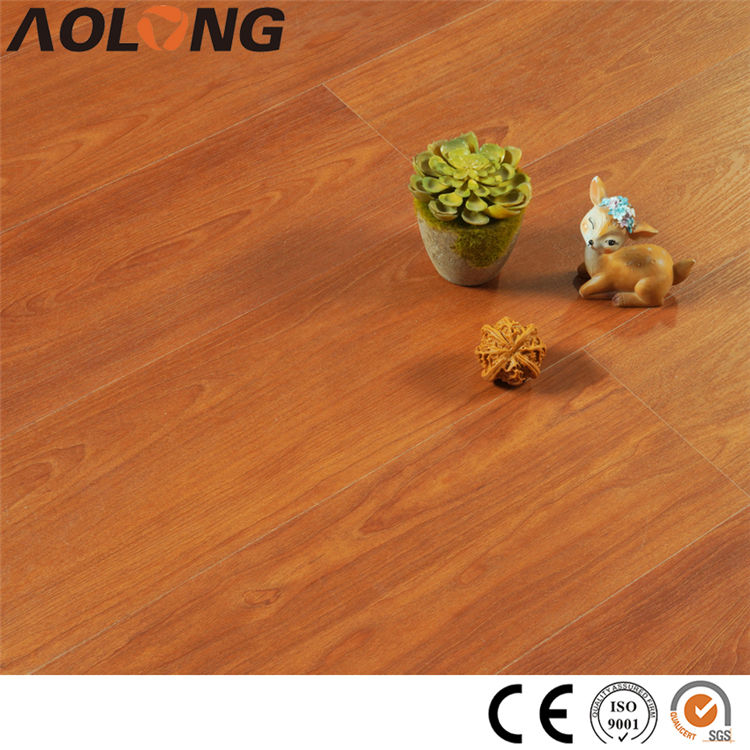

| Surface Texture | Wood Texture |

| Overall Thickness | 10.5mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1200 * 178 * 10.5mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our administration ideal for Renewable Design for Rigid Core Vinyl Flooring - WPC Floor 1055 – Aolong, The product will supply to all over the world, such as: Iraq, Nigeria, Jamaica, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Let us work together to write a brilliant new chapter!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!