Renewable Design for Exterior Floor Tiles - WPC Floor M005 – Aolong Detail:

Wood plastic materials are flexible and can be used in any field of wood processing to replace the best environmentally friendly materials of wood, wood plastic products play a vital role in the country’s low energy consumption, is a recyclable product, the country’s major projects are widely used.

Raw materials of high-quality, formula scientific wood plastic door of the main raw materials are PVC resin and high-quality wood powder, PVC resin using medical grade domestic brand-name products, wood powder by professional wood companies to provide high-quality tree wood powder, after grading screening, grinding, drying, coating treatment, to ensure that the finished product on the quality of raw materials requirements. Wood plastic door formula system is equipped with a certain proportion of auxiliary materials, into stabilizers, foaming agents, modifiers, etc. , a variety of ingredients according to strict ratio mixing, effectively ensure the quality of foam plate products.

Advanced production equipment production equipment is from the mixing system to the extrusion system all imported from abroad, ranking the international leading level, high degree of automation, in which mixing equipment with precise dosage, mixing uniform, high efficiency characteristics, fundamentally ensure the stability of the product. Due to the high requirements of wood-plastic foaming door production for foaming extrusion equipment, and the use of high torque twin screw extruder, and screw, screw and other components for modification, to adapt to the inside and outside surface of lignin crust and uniform foaming, to avoid the occurrence of wood-powder carbonization and other phenomena.

| Specification | |

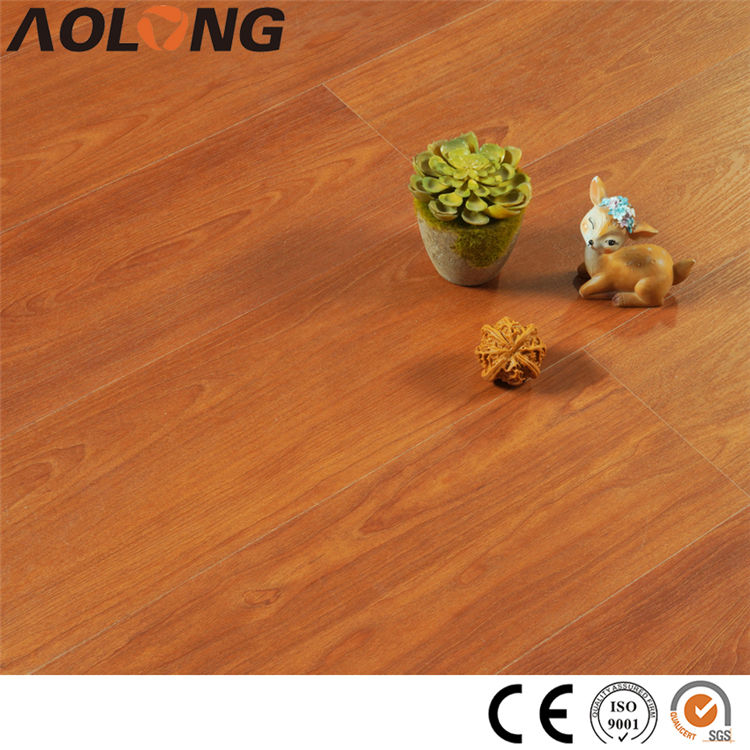

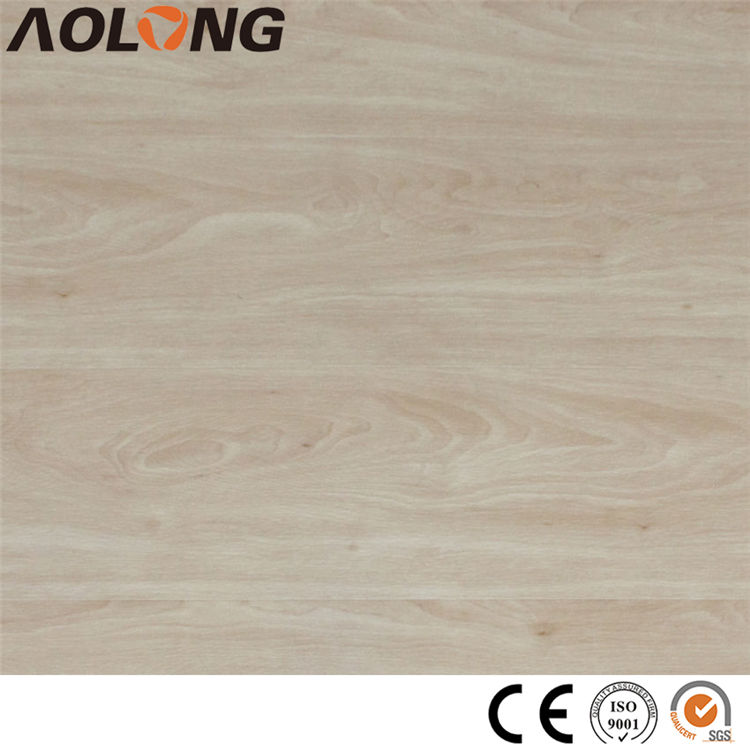

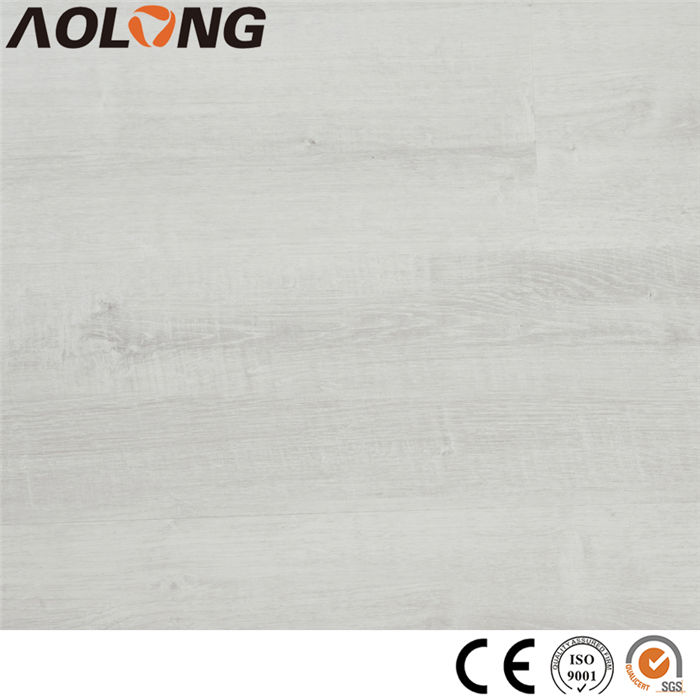

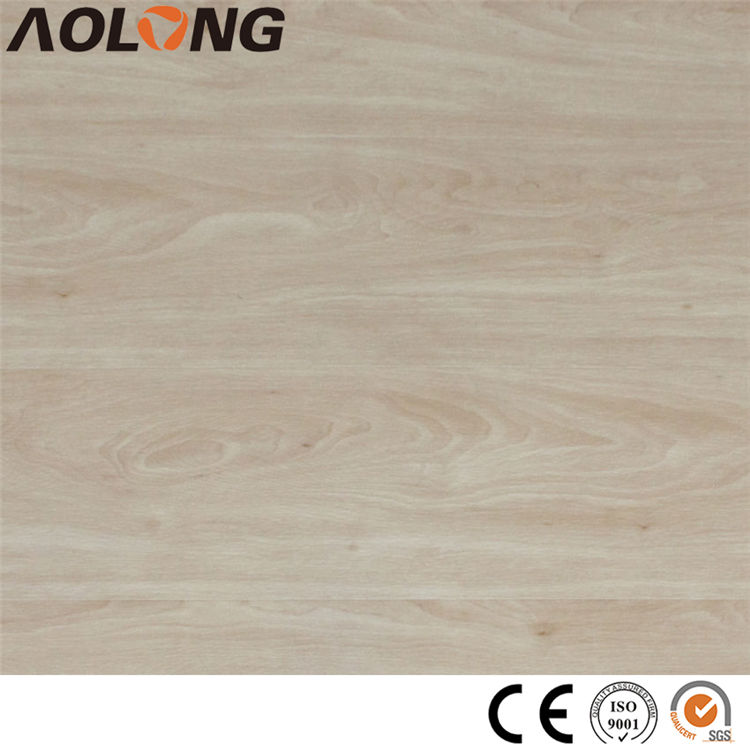

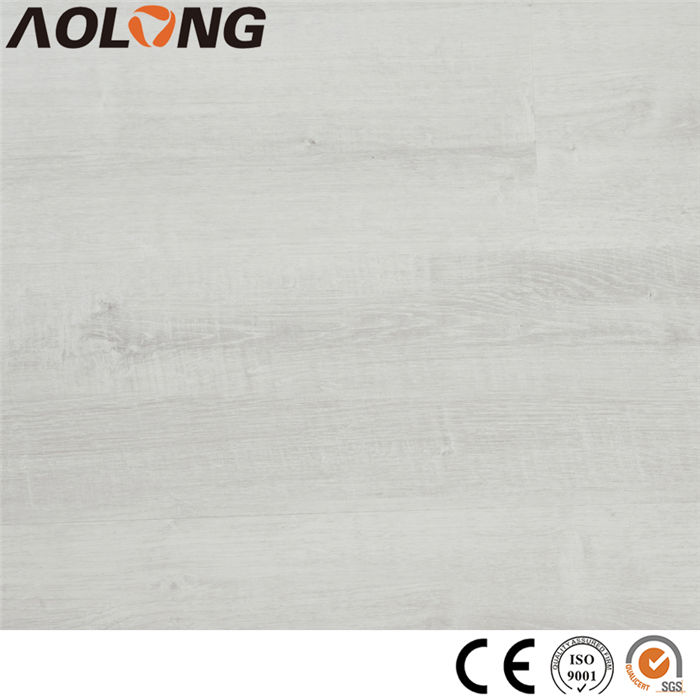

| Surface Texture | Wood Texture |

| Overall Thickness | 8mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1200 * 180 * 8mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth, will proceed to provide aged and new buyers from home and abroad whole-heatedly for Renewable Design for Exterior Floor Tiles - WPC Floor M005 – Aolong, The product will supply to all over the world, such as: Turkey, Swaziland, Argentina, During in 11 years, We have participated in more than 20 exhibitions, obtains the high praise from each customer. Our company has been devoting that customer first and committed to helping customers expand their business, so that they become the Big Boss !

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!

-

China Wholesale Office Floor Tiles Pricelist &#...

-

China Wholesale Project Floors Vinyl Suppliers ...

-

China Wholesale Deep Embossed Spc Flooring Pric...

-

Wholesale Dealers of Outside Wpc Flooring 26x14...

-

China Wholesale Self Adhesive Vinyl Floor Tiles...

-

China Wholesale Plastic Spc Flooring Pricelist ...