Factory source Rvp Rigid Vinyl Plank Spc Flooring 4mm - SPC Floor 1903 – Aolong Detail:

Difference between LVT floor / SPC floor / WPC floor

The flooring industry has developed rapidly in the past decade, and new types of flooring have emerged, such as LVT flooring, WPC wood plastic flooring and SPC stone plastic flooring. Let’s take a look at the differences among these three types of flooring.

1 LVT floor

LVT floor production process: the biggest feature of its production process is the production of each layer of LVT sheet, which is generally processed into 0.8 ~ 1.5mm thick sheet by “internal mixing + calendering” method, and then made into the required thickness of the finished floor product by assembling and hot pressing.

2 WPC floor

WPC floor production process: it can be seen from the product structure diagram that WPC floor is a composite floor containing LVT and WPC substrate. The technological process is as follows: first, the LVT floor with single layer structure is made, then the extruded WPC substrate is pressed and pasted with adhesive, and the adhesive used is polyurethane cold pressing adhesive.

3 SPC floor

SPC floor production process: similar to WPC floor base material, SPC base material is extruded and calendered into sheet board by extruder, and then pasted with color film and wear-resistant layer on the surface. If it is ab or ABA structure of SPC composite floor, the SPC base material is extruded first, and then the LVT layer is pressed and pasted by the way of green combination.

The above is the difference between LVT flooring, WPC flooring and SPC flooring. These three new types of flooring are actually derivatives of PVC flooring. Because of their special materials, these three new types of flooring are more widely used than wood flooring, and are widely popular in European and American markets, while the domestic market still needs to be popularized

| Specification | |

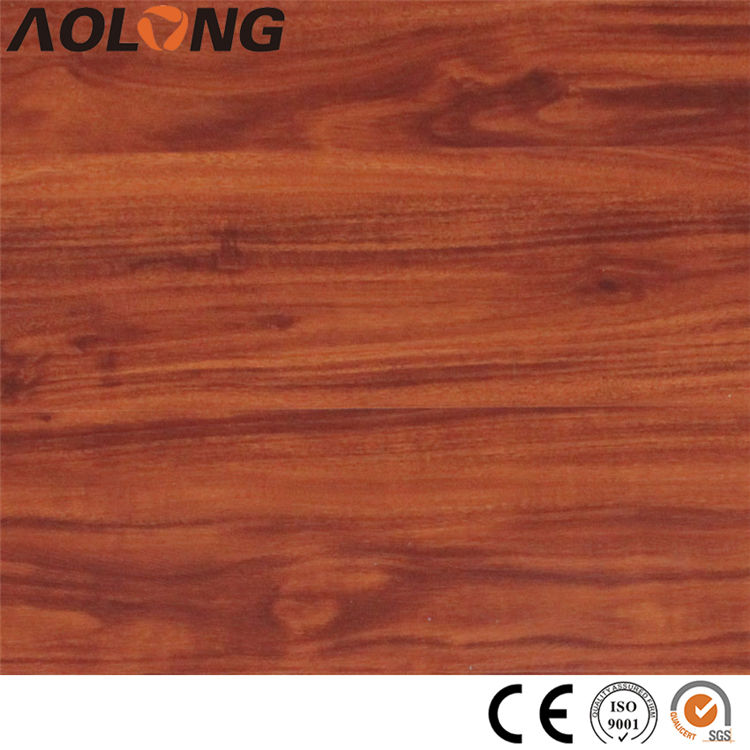

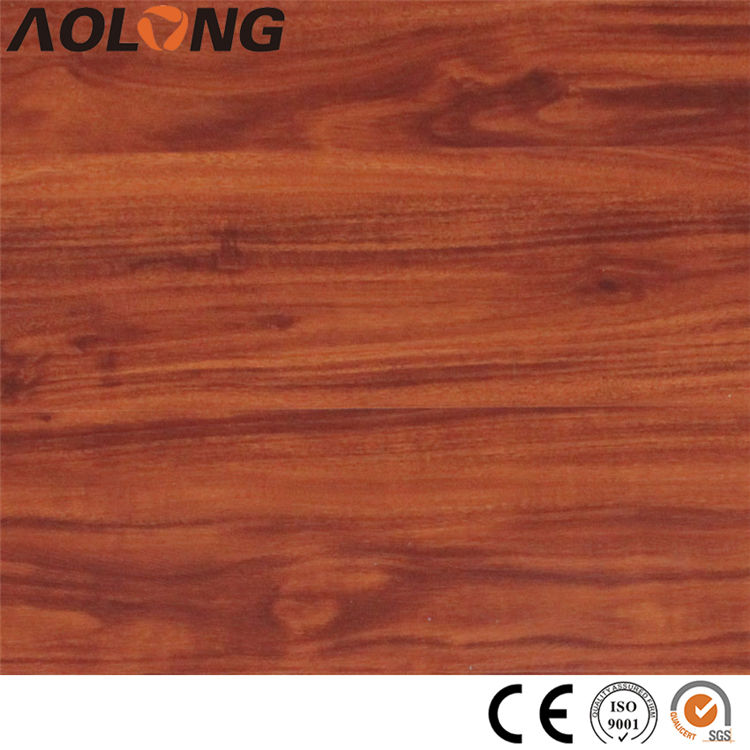

| Surface Texture | Wood Texture |

| Overall Thickness | 6mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1210 * 183 * 6mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |

Product detail pictures:

Related Product Guide:

We keep improving and perfecting our products and service. At the same time, we work actively to do research and development for Factory source Rvp Rigid Vinyl Plank Spc Flooring 4mm - SPC Floor 1903 – Aolong, The product will supply to all over the world, such as: Estonia, Canberra, Zurich, We welcome you to visit our company and factory. It is also convenient to visit our website. Our sales team will offer you whole heartedly service. If you need more information, please feel free to contact us by E-mail or telephone. We are sincerely hope to establish a good long-term business relationship with you through this opportunity, based on equal, mutual benefit from now till the future.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

-

China Wholesale Parquet Vinyl Flooring Factorie...

-

China Wholesale Spc Waterproof Click Vinyl Floo...

-

China Wholesale Spc Rigid Core Vinyl Flooring Q...

-

China Wholesale Trendy Vinyl Flooring Manufactu...

-

Professional Design Vinyl Flooring Roll - WPC ...

-

2021 New Style Spc Flooring Planks - SPC Floor...